All

Latest News

Publications

New paper favourably compares the Micron Horizontal Track Sprayer with the ‘gold standard’ Potter Spray Tower to treat surfaces for IRS evaluation

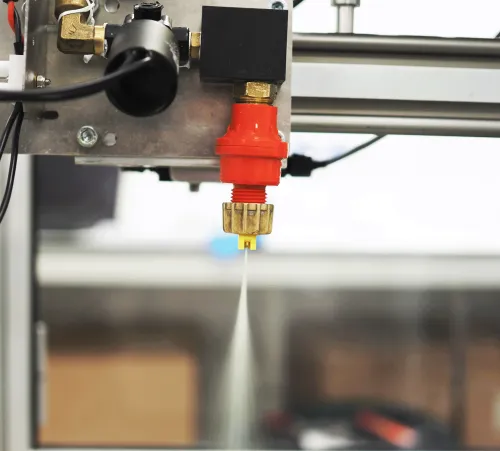

For laboratory evaluation of the bioefficacy and residual efficacy of indoor residual spray (IRS) products, the standard testing methodology involves applying the formulation to a test surface and exposing mosquitoes to this surface using a WHO cone test to measure knock down and mortality. The industry standard laboratory sprayer is the Potter Spray Tower, but researchers and product developers have long noted challenges in using this equipment, including the long time taken to centre and calibrate the spray deposit, and the fact that it can be difficult to source suppliers and specialists to service the equipment. The need for improved methods to accurately and reproducibly apply spray deposits onto test surfaces was noted by industry partners as a priority in the development and evaluation of IRS products in an I2I consultation on methods.

The potential of the Track Sprayer in laboratory and semi-field settings has previously been shown by researchers, including members of the I2I Methods Validation team, to deliver more accurate and consistent spray deposits than the hand-held sprayer often used to treat test surfaces. A paper recently published in Parasites and Vectors demonstrates that the Micron Horizontal Track Sprayer, developed by Micron Sprayers, also represents a significant improvement over the Potter Spray Tower. Results of a series of studies are presented which compare uniformity of spray deposits, efficiency of delivery, throughput and operating times and the resulting cost.

This work was a collaboration between I2I and LSTM researchers, IVCC and Micron Sprayers, coordinated by Jane Bonds of Bonds Consulting Group LLC. Standard operating procedures (SOPs) for the operation of both the Track Sprayer and Potter Tower are available as supplementary information in the paper and on the I2I website.

“As a consultant on this project, I found the whole concept at first surprising. During my masters, we had used a potter tower we operated with full body suits and respirators due to the outflow of chemicals into the room from the base of the unit. The lab set up in a fume hood took up less space but was still slow with only one surface sprayed at a time. The track sprayer does provide a contained system capable of spraying several surfaces at once in a more uniform fashion. The manufacturers took on some of our concerns from this comparative study and have upgraded the track sprayer accordingly. This was a great team to work with identifying new methods that will help us in our search for newer safer compounds for IRS and other studies” – Jane Bonds, Bonds Consulting Group LLC

Access to the paper “Comparative analysis of the Potter Tower and a new Track Sprayer for the application of residual sprays in the laboratory”